When it comes to custom apparel design and printing services, screen printing stands out as our premier technique, cherished for its ability to bring vivid designs to life on a myriad of textiles. This time-honored method comes in two primary forms: manual and automatic presses, each catering to distinct needs and scales of production. As businesses strive to make their mark with unique branded merchandise, the choice between these two types of presses becomes crucial.

Screen printing is not just a printing process; it’s an art form that combines creativity with precision. Manual presses, operated by skilled artisans, allow for meticulous control over each print, making every piece a testament to craftsmanship. This method is ideal for custom, boutique orders where each item is a reflection of individual artistry and attention to detail.

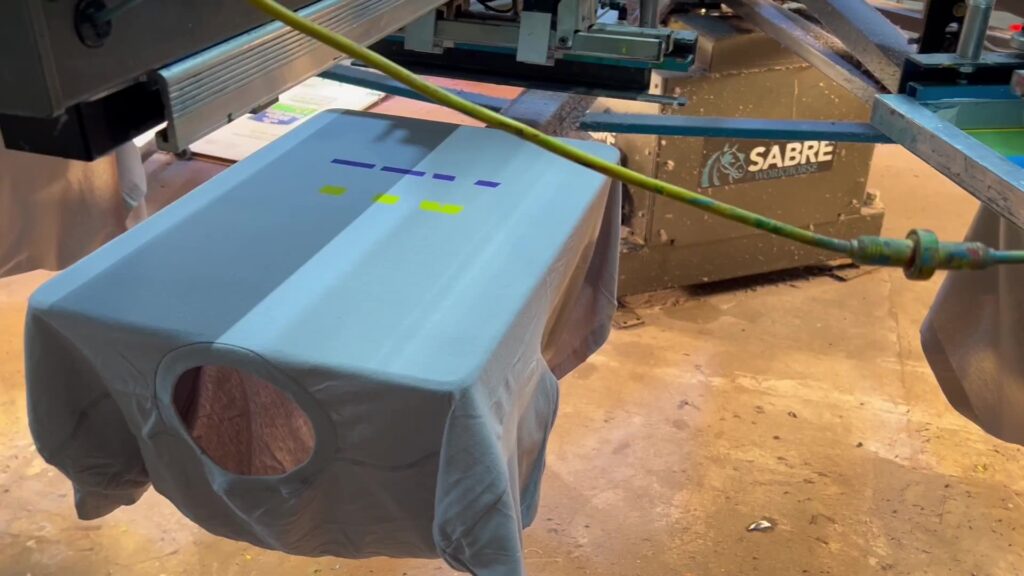

On the flip side, automatic presses represent the pinnacle of efficiency and consistency in screen printing. These machines are engineered to handle high volumes swiftly, maintaining uniform quality across thousands of prints. They are the backbone of major printing operations, where the demand for quick turnaround times meets the need for large-scale order fulfillment. Automatic presses minimize human error and maximize output, making them indispensable for businesses aiming to expand their reach without compromising on quality.

Whether you’re a burgeoning startup or a well-established brand, understanding these printing options is key to optimizing your investment in custom apparel. The decision to choose between manual and automatic presses hinges on your project’s volume, design complexity, and budget constraints. Each method offers distinct advantages that can enhance your brand’s visibility and appeal.

Manual vs. Automatic Presses

Screen printing machines generally fall into two categories: manual presses and automatic presses. Manual presses require the operator to manually load and unload shirts, as well as operate the squeegee by hand. This method is labor-intensive but provides a high level of control, making it ideal for small batches or highly customized orders.

On the other hand, automatic presses streamline the printing process through mechanization. These presses automatically handle the squeegees, and the shirts advance from one station to the next without manual intervention. This setup is perfect for large volume orders where consistency and speed are paramount. An automatic press can dramatically increase production rates, boasting the ability to produce thousands of shirts in a single day.

Cost Considerations

The initial investment for manual presses is typically lower, making them a good entry point for smaller print shops or those just starting out. Automatic presses, while more costly upfront, offer greater efficiency and lower labor costs per shirt as production scales up.

Production Speed and Efficiency

Automatic presses are significantly faster than manual ones. For instance, industry records highlight that an experienced operator on an automatic press can produce over a thousand shirts per hour. In contrast, a manual press might produce between 40 to 100 shirts per hour, depending on the complexity of the design and the skill of the operator.

Choosing the Right Press for Your Needs

The choice between manual and automatic presses hinges on several factors:

- Volume: High-volume orders are more cost-effective on automatic presses.

- Complexity of Design: Automatic presses handle complex multi-color designs more efficiently.

- Cost: Smaller orders or limited budgets may benefit from the manual process.

Future of Screen Printing

While manual screen printing has a rich history and retains its place for specific applications, technological advancements are paving the way for more automated solutions. Direct-to-Garment (DTG) printing is also rising as a popular alternative, offering even faster turnaround times for certain types of orders.

Choosing between a manual and an automatic press involves considering your business’s current needs and future growth. While automatic presses represent a higher initial investment, they can lead to significant savings in time and labor with increased production capacity. On the other hand, manual presses offer flexibility and lower costs for startups or small-scale operations. Each type of press has its role in the diverse world of screen printing, ensuring that all business sizes and types can find a suitable printing solution.